PRODUCTS

Carbonyl iron powder

本公司产品广泛应用于电力、化工、石油、天然气企业、冶金企业、热力管网、造船、造纸、建筑等行业的管道工程。产品销往全国 30 多个省、市、自治区,并先后出口到印尼、印度、泰国、缅甸、沙特、阿联酋等国家。

Key words:

Carbonyl iron powder

Product description

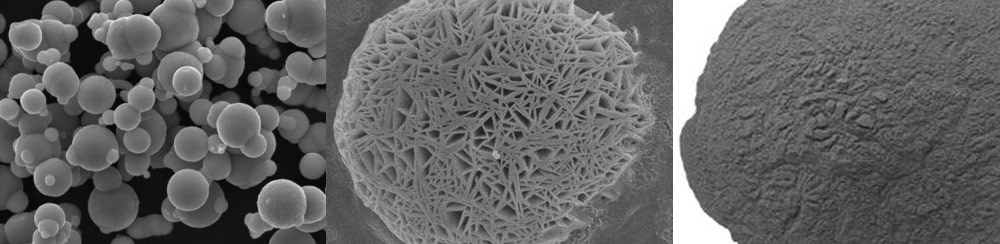

Powder characteristics:

Grey ultrafine powder, spherical particles, onion-like structure. Carbonyl iron powder has the characteristics of extremely high purity, good fluidity, dispersibility, high activity, excellent electromagnetic properties, and good press and sinter moldability.

Application areas:

Carbonyl iron powder is an ultra-fine metal powder prepared by the thermal decomposition of pentacarbonyl iron Fe (CO) 5. Due to its small particle size (below 10um), high activity and irregular shape (layered structure of onion head), it has many unique properties Therefore, it is widely used in military, electronics, chemical, pharmaceutical, food, agriculture and other fields.

Packing:

Packed in iron drums, 25 kg / barrel, 50 kg / barrel, palletized. Can also be packed according to customer's special requirements

Carbonyl iron powder grade implementation standards

| Grade | Chemical Composition | Physical Properties | |||||||

| Fe% | C% | N% | O% | Bulk Density(g/m³) | Tap Density(g/m³) | Particle Size Distribution(μm) | |||

| D10 | D50 | D90 | |||||||

| JCF1-1 | ≥98 | ≤0.80 | ≤0.80 | ≤0.4 | ≥2.2 | ≥4.0 | ≥0.5 | ≤3.5 | ≤9.0 |

| JCF1-2 | ≥98 | ≤0.80 | ≤0.80 | ≤0.4 | ≥2.5 | ≥3.9 | ≥1.5 | 3.5-4.5 | ≤12.0 |

| JCF1-3 | ≥98 | ≤0.80 | ≤0.80 | ≤0.4 | ≥2.5 | ≥3.8 | ≥2.0 | 4.5-7.0 | ≤18.0 |

| JCF1-4 | ≥98 | ≤0.90 | ≤0.90 | ≤0.4 | ≥2.2 | ≥3.5 | ≥2.5 | 7.0-8.5 | ≤21.0 |

| JCF1-5 | ≥98 | ≤0.90 | ≤0.90 | ≤0.4 | ≥2.2 | ≥3.5 | ≥3.0 | ≥8.5 | ≤25.0 |

Application:MIM、Powder Metallurgy、Diamond Tools、Diamond catalysts、Microwave Absorption、Magnetic Materials.

Carbonyl iron powder grade implementation standard (reduction)

| Grade | Chemical Composition | Physical Properties | |||||||

| Fe% | C% | N% | O% | Bulk Density(g/m³) | Tap Density(g/m³) | Particle Size Distribution(μm) | |||

| D10 | D50 | D90 | |||||||

| JCF2-1 | ≥99.5 | ≤0.05 | ≤0.01 | ≤0.3 | ≥2.5 | ≥3.8 | ≥0.5 | 2-4.5 | ≤12.0 |

| JCF2-2 | ≥99.5 | ≤0.05 | ≤0.01 | ≤0.3 | ≥2.5 | ≥3.8 | ≥1.5 | 4.5-7.0 | ≤18.0 |

| JCF2-3 | ≥99.5 | ≤0.05 | ≤0.01 | ≤0.25 | ≥2.5 | ≥3.6 | ≥2.5 | 7.0-10.0 | ≤25.0 |

| JCF2-4 | ≥98.5 | ≤0.40 | ≤0.20 | ≤0.3 | ≥2.5 | ≥3.6 | ≥1.5 | 4.5-10.0 | ≤25.0 |

Application:Powder Metallurgy、Diamond Tools、MIM

Carbonyl iron powder grade implementation standard (preally powder)

| Grade | Chemical Composition | Physical Properties | |||||||

| Fe% | C% | N% | O% | Ni | Mo | Particle Size Distribution(μm) | Bulk Density(g/m³) | Tap Density(g/m³) | |

| Fe2Ni | 余量 | ≤0.80 | ≤0.80 | ≤0.40 | 1.8-2.2 | 0.4-0.6 | 4.5-5.5 | ≥2.5 | ≥3.8 |

| Fe4Ni | 余量 | ≤0.80 | ≤0.80 | ≤0.40 | 3.8-4.2 | 0.4-0.6 | 4.5-5.5 | ≥2.5 | ≥3.8 |

| Fe8Ni | 余量 | ≤0.80 | ≤0.80 | ≤0.40 | 7.8-8.2 | 0.4-0.6 | 4.5-5.5 | ≥2.5 | ≥3.8 |

Application:MIM

Note: C and other metallic element can be added per customer`s requirement

Carbonyl iron powder grade implementation standard (Integrated inductance、Magnetic )

| Grade | Chemical Composition | Physical Properties | Note | ||||||||||

| Fe% | C% | N% | O% | Si% | Magnetic Properties | Bulk Density(g/m³) | Tap Density(g/m³) | Particle Size Distribution(μm) | |||||

| Perm. | Q | D10 | D50 | D90 | |||||||||

| JCF4-1 | ≥98 | ≤0.80 | ≤0.60 | ≤0.4 | 10-12 | 130-150 | ≥2.5 | ≥4.0 | ≥0.5 | ≤3.5 | ≤9.0 | ||

| JCF4-2 | ≥98 | ≤0.80 | ≤0.60 | ≤0.4 | 11-14 | 120-140 | ≥2.5 | ≥3.9 | ≥1.5 | 3.5-4.5 | ≤12.0 | ||

| JCF4-4 | Bal. | ≤0.05 | ≤0.01 | ≤0.6 | 0.1-0.3 | 28-31 | 110-130 | ≥2.5 | ≥3.8 | ≥0.5 | ≤4.5 | ≤12.0 | |

| JCF4-5 | Bal. | ≤0.05 | ≤0.01 | ≤0.6 | 0.1-0.3 | 31-35 | 100-120 | ≥2.5 | ≥3.8 | ≥1.5 | 4.5-7.0 | ≤18.0 | |

| JCF4-6 | Bal. | ≤0.05 | ≤0.01 | ≤0.6 | 0.1-0.3 | 35-40 | 90-110 | ≥2.5 | ≥4.0 | ≥2.5 | 7.0-10.0 | ≤25.0 | |

| JCF4-4L | Bal. | ≤0.05 | ≤0.01 | ≤0.6 | 0.2-0.5 | 28-31 | 110-130 | ≥2.5 | ≥3.8 | ≥0.5 | ≤4.5 | ≤12.0 | insulation |

| JCF4-5L | Bal. | ≤0.05 | ≤0.01 | ≤0.6 | 0.2-0.5 | 31-35 | 100-120 | ≥2.5 | ≥3.8 | ≥1.5 | 4.5-7.0 | ≤18.0 | insulation |

| JCF4-6L | Bal. | ≤0.05 | ≤0.01 | ≤0.6 | 0.2-0.5 | 35-40 | 90-110 | ≥2.5 | ≥4.0 | ≥2.5 | 7.0-10.0 | ≤25.0 | insulation |

Application:Integrated inductance、Magnetic Materials

Carbonyl iron powder grade implementation standard (Microwave absorption)

| Grade | Chemical Composition | Physical Properties | |||||||

| Fe% | C% | N% | O% | Bulk Density(g/m³) | Tap Density(g/m³) | Particle Size Distribution(μm) | |||

| D10 | D50 | D90 | |||||||

| JCF5-1 | ≥98 | ≤0.80 | ≤0.80 | ≤0.4 | ≥2.0 | ≥3.9 | ≥1.5 | 3.5-4.5 | ≤12.0 |

| JCF5-2 | ≥98 | ≤0.90 | ≤0.80 | ≤0.4 | ≥2.5 | ≥3.9 | ≥2.0 | 4.5-7.0 | ≤18.0 |

| JCF5-3 | ≥98 | ≤0.90 | ≤0.80 | ≤1.0 | ≥1.0 | ≥2.0 | flake:thickness0.2-0.5μm、diameter5-10μm | ||

| JCF5-4 | ≥98 | ≤0.90 | ≤0.80 | ≤1.0 | ≥1.0 | ≥2.0 | flake:thickness0.5-1.0μm、diameter5-10μm | ||

Application:Microwave Absorption

Product inquiry

相关产品

undefined

Service Hotline: South China region15124358911/East China region13634423569

If you have any questions, please feel free to contact us